Innovations in Coil Coating: COMAX sheets painted on both sides

In Coil Coating, the choice of material plays a decisive role, both in terms of aesthetics and function. In recent years, double-sided painted sheet metal has become one of the most popular materials for fitters thanks to its excellent properties and wide range of applications. In this article, we will look at the properties, advantages and possible applications of COMAX sheets painted on both sides.

Characteristics

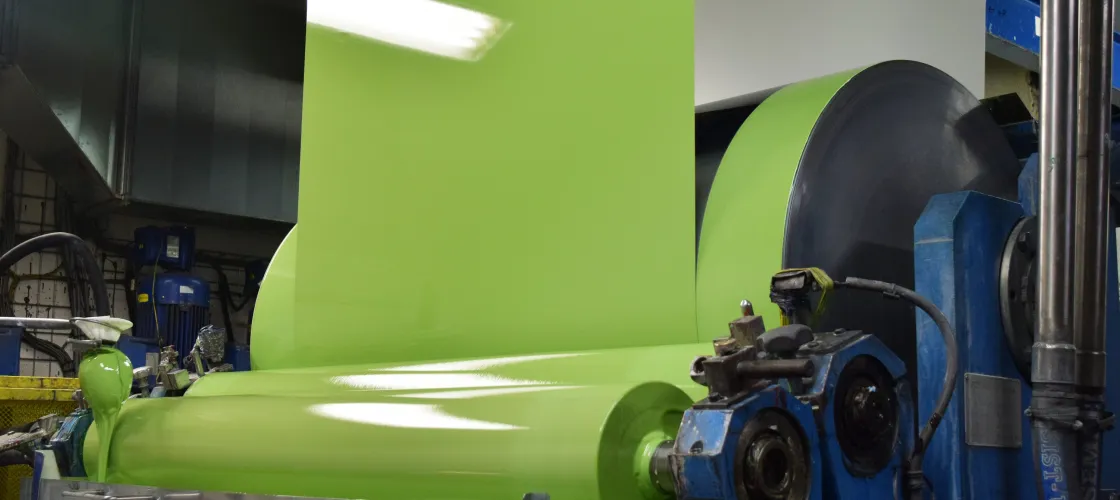

These painted COMAX sheets are coated on both sides with a protective layer of paint in the same color and thickness - 25 microns. This is usually a galvanized steel sheet, which is then painted with special polyester-based paints. Painting on both sides not only ensures greater corrosion resistance, but also improves the overall aesthetics of the product.

One of the most important features of double-sided painted sheet metal is its high resistance to weathering and mechanical damage. These properties make this material suitable for use in demanding environmental conditions where the aesthetic appearance and functionality must be maintained over the long term.

Application

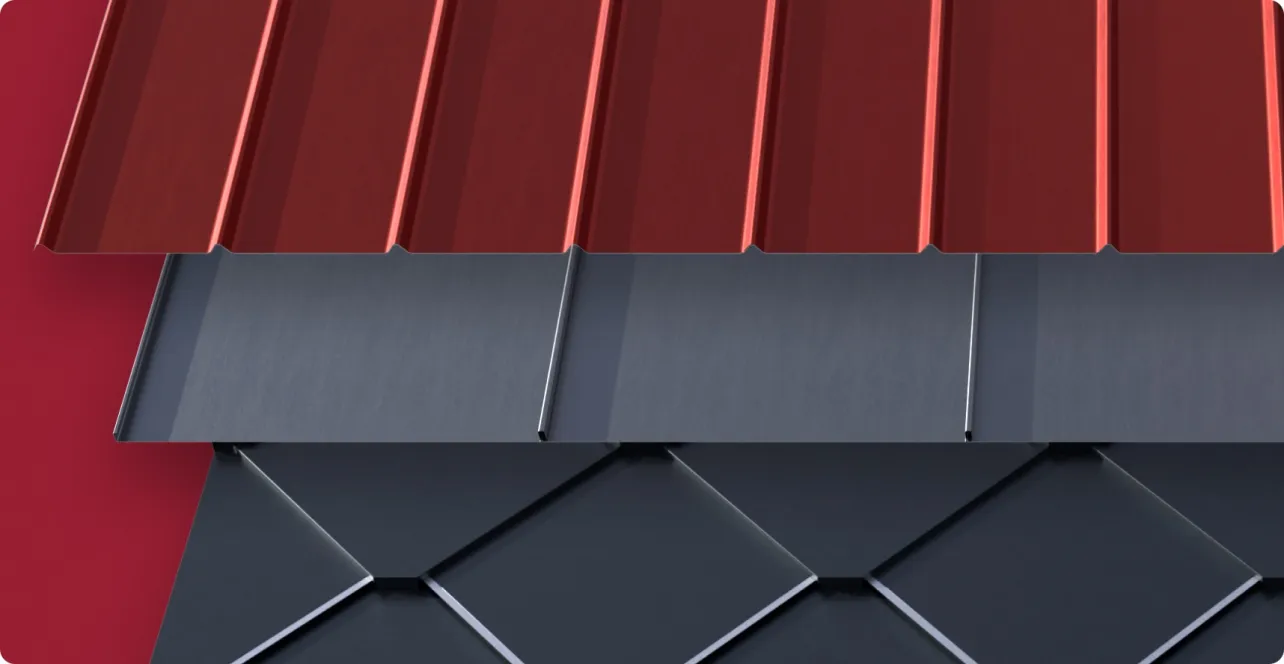

These COMAX sheets, painted on both sides, are of high quality and are ready for immediate dispatch thanks to stock production. They are mainly used for the production of roof coverings for open roofs, where the underside of the sheet also plays an important role and must have the same color as the top side.

Window sills made of sheet metal painted on both sides are another important product. The window sills not only protect the lower part of the windows from rain, but also contribute to the aesthetics of the entire façade. The double-sided painted surface gives the window sills a long service life and ensures that they do not warp or deform due to moisture and temperature fluctuations.

Facade cladding

Thanks to its weather resistance, this material is often used for cladding modern buildings where the emphasis is on clean lines and a long façade life.

The sheet, which is painted on both sides, is used in particular in the manufacture of chimney cladding and various roof details such as gutters, ridges and ridges. These parts of the roof are often exposed to extreme conditions, so it is important that they are made from a material that offers maximum protection.

COMAX sheets painted on both sides offer excellent resistance to moisture and mechanical damage, so that they fulfill their protective function in the long term.

What can we say in conclusion?

COMAX sheets painted on both sides represent a significant advance in coating practice, bringing not only technical but also aesthetic benefits. Thanks to their properties and wide range of applications, they are increasingly becoming the first choice for many projects. Whether for roofs, façades or other building elements, this material offers the ideal combination of durability, aesthetics and longevity.

And let's not just be serious. Do you know why you'll never have a hard time deciding on a COMAX sheet painted on both sides? Because no matter which side you choose, it's always the right one!

Advantages of double-sided painted sheets from COMAX:

- tradition. We have been painting sheets on both sides for more than 15 years.

- long service life. Painting on both sides gives the sheet metal excellent corrosion protection, which significantly extends its service life.

- aesthetic variability. We offer sheets painted on both sides in a wide range of colors, which gives architects and designers, for example, a great deal of freedom in designing the appearance of buildings. Our permanent range includes 17 basic colors in combinations with sheet thicknesses of 0.50 mm and 0.55 mm.

- universally applicable. Thanks to its properties, this sheet is suitable for roofing as well as for façade cladding, chimney cladding, window sills or cladding of various roof details.

- ecological. We offer painted sheets with environmentally friendly surfaces that are free of harmful substances. All this is confirmed by a certificate for painted sheet metal.

- Protective Film. Since May 2024, our COMAX sheets painted on both sides have been provided with an 80 micrometer thick protective Film. The film is white and printed with information about the relevant standard for curved elements. It can be easily removed and provides adequate protection for the sheet metal product until it is actually installed. We believe that this important production change represents a step into a higher quality class.